PRIMARY

EFFLUENT TREATMENT PLANT (PETP)

PARAMETERS

OF TREATED WATER for HOTELS , HOSPITALS and other industries currently accepted

by Pollution Control Board of Assam. (PCBA)

The

parameters of the treated effluent water will be as under meeting norms of Pollution control

Board (PCBA) .

pH Between 5.5 to 9

TSS (Total suspended solid below 150 mg/liter

BOD( Biological oxygen demand) less than 30 mg/liter

COD(Chemical oxygen demand) less than 250 mg/liter

Oil & grease less than 10 mg/liter

pH Between 5.5 to 9

TSS (Total suspended solid below 150 mg/liter

BOD( Biological oxygen demand) less than 30 mg/liter

COD(Chemical oxygen demand) less than 250 mg/liter

Oil & grease less than 10 mg/liter

IF WASTE WATER FROM HOTEL, HOSPITAL EXCEEDS

THE ABOVE VALUE, ONE PETP IS TO BE INSTALLED FOR TREATING WASTE WATER AND BRING

IT WITHIN LIMITS MENTIONED ABOVE.

Our Consultancy & Supervision scope:

We offer our work on consultancy basis for the Hotels

,hospitals, restaurants, wedding hall, ccar service station, tea garden and

other industries. . All the civil & execution work will be done

by the respective Hotel , under our

guidance from initial survey to the final report submission to the Pollution

Control Board of Assam (PCBA).

1.Preparation

of drawing as per site condition for each

location of hotels , it’s size , their

complexity and need of the hotel

. Thus there is no common solution for all hotels if Customized concept

is adopted , So will provide customized system plant for each

site. Also, at various sites there are exiting septic tanks and other tanks

,pipes etc which can be adjusted in our proposed system which will reduce

construction cost.

2 . We shall Provide a Flow

Chart & project report for

submission to the PCBA

3.We will supervise the progress

of the civil works during construction time of the ETP.

4.We will provide you a

list of dealers from where you can buy

the pump , blower and chemicals.

5..We will train your staff

for first 3 days how to run the plant & provide a maintenance manual for

the plant

6. We will provide a first water test report to be submitted to pollution board

7. We shall help in filling of the Documents to be submitted to the

PCBA . All the legal fees & dues needs to be cleared by the client . The

extra cost for Consent to operate or NOC is not included in the Consultancy

DATA

REQUIRED:

a)Quantity of waste

water generated liter per day

b) Waste Water test report .

.

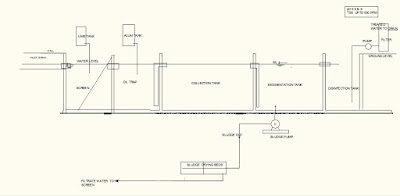

TREATMENT METHOD OF PETP:

Chemical pre treatment followed by filtration

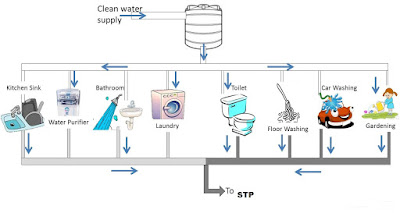

Flow

Chart of PETP:

IN-Screen—Oil Trap---Collection

Tank---Primary Sedimentation--— ------Disinfection Tank—Pump---Filter ----Out

to drain

Details of different units of the proposed system

A)CHEMICAL

TREATMENT OF WASTE WATER IN PETP

a)

Screen :Waste water will flow through these drains

by gravity flow from the inlet manhole. To remove large floating objects , bar

screens and oil traps are provided inside the incoming drain itself .

b)

Collection tank: All waste water will be collected

here .Lime and Alum will be added here and mixed by air bubbling from a air blower..Waste

water will flow by gravity to the next unit.

c)

Primary Sedimentation tank(PST): The chemical

sludge will be settled here. Waste water will flow by gravity to the next unit.

Sludge is removed by sludge pump to sludge drying beds.

d)Disinfection tank : Disinfection is done here with bleaching powder to

remove colour, bactaria and other

contaminants and than pumped to the pressure

sand filter and finally released to drain.